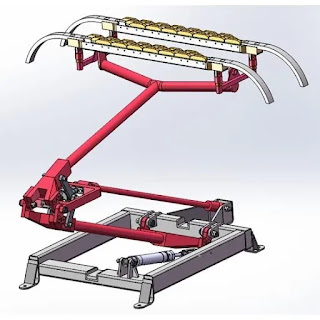

Testing the Pantograph Power

Pantograph Load Testing for Electric Trains A pantograph load test machine is a specialized system used to evaluate and simulate the performance of pantographs, which are critical components in electric trains. Complex Environment and Challenges The pantograph is the component of an electric train that makes contact with the overhead trolley wire (catenary system) to draw power. The environment where the pantograph touches the wire is incredibly complex: Catenary systems exhibit varying vertical stiffness along their length. The wires zigzag at intervals (typically 30 to 100 meters) to prevent grooving. The force applied by the pantograph to the wire must stay within a well-defined range (usually between 70N and 120N). Too little force results in loss of contact, arcing, and damage to the wire and contact bar. Too much force causes premature wear on the wire and contact bar due to friction. Delivering the right amount of force ...