Testing the Pantograph Power

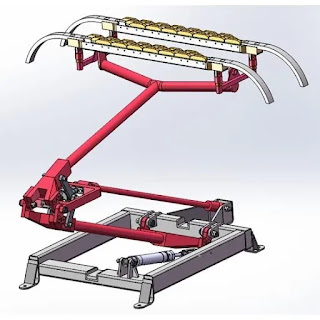

Pantograph Load Testing for Electric Trains

A pantograph load test machine is a specialized system used to evaluate and simulate the performance of pantographs, which are critical components in electric trains.

Complex Environment and Challenges

- The pantograph is the component of an electric train that makes contact with the overhead trolley wire (catenary system) to draw power.

- The environment where the pantograph touches the wire is incredibly complex:

- Catenary systems exhibit varying vertical stiffness along their length.

- The wires zigzag at intervals (typically 30 to 100 meters) to prevent grooving.

- The force applied by the pantograph to the wire must stay within a well-defined range (usually between 70N and 120N).

- Too little force results in loss of contact, arcing, and damage to the wire and contact bar.

- Too much force causes premature wear on the wire and contact bar due to friction.

- Delivering the right amount of force requires variable vertical motion, especially at high speeds.

Testing Challenges:

- Recreating the dynamic pantograph environment in the lab is complex:

- Pantographs travel at speeds up to 350 kph (220 mph) and carry enough power to accelerate heavy rail cars.

- Traditional spin/slide tests using spinning discs and carbon specimens do not fully replicate real-world dynamics.

- These tests involve pushing a piece of carbon against a spinning wire, but they lack the full complexity of actual pantograph operation.

Advanced Testing Systems:

- New pantograph testing systems aim to simulate operational dynamics more precisely.

- These systems measure various parameters, including:

- Contact forces: Load cells allow precise measurement of the forces exerted by the pantograph.

- Lateral movement: Motor servo-actuators reproduce the catenary stagger, allowing to travel pantograph to achieve its maximum height up to 4000mm with respect to the central axis of the pantograph.

- Frequency and acceleration: The system can operate at frequencies up to 1.5 Hz and accelerations of up to 2.7 g.

- The goal is to understand the interaction between the pantograph and catenary system accurately, ensuring safe and efficient rail operation.

TEST CASE

- Holding the pantograph in test in a fixed, known, repeated position near the testing machine

- Appling a pneumatic air to rise the pantograph lifting.

- Measuring

- Applied static load

- Distance traveled pantograph height

- Observation and Adjustment of the pantograph by Graph with in the limits.

DESIGN

- Power supplies

- Cabinet

- Control Pc

- Servo drives

- Safety button

SOFTWARE

- Operator Login Interface

- Live data Graph Interface

- Settings Interface

FUTURE

The Adjustment of the pantograph fine turning error message pop up will be provided.

Comments

Post a Comment