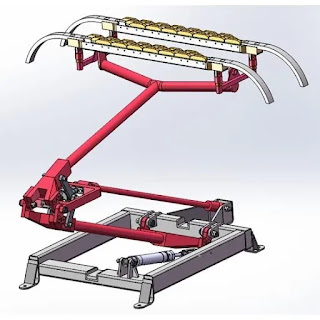

Revolutionizing Railway Safety In the pursuit of advancing railway safety and efficiency, Novatek has embarked on a groundbreaking project to develop an Automated Test Bench that performs functional tests on braking systems used in railways. This innovative solution is set to transform the way railway systems ensure the reliability and effectiveness of their critical safety components. The Need for Innovation in Railway Braking Systems Railway braking systems are vital for the safe operation of trains, requiring regular and rigorous testing to maintain performance standards. Traditional methods of brake testing are often manual, time-consuming, and not always capable of detecting certain types of failures. Novatek’s Automated Test Bench addresses these challenges head-on, offering a risk-based, efficient, and reliable testing process. Introducing Novatek’s Automated Test Bench Novatek’s Automated Test Bench is designed with precision and adaptability in mind. Utilizing state-...

Comments

Post a Comment